Wärtsilä FuTube Package advancement in ship operations technology

FuTube shaft line solution package

The shaft line sits at the core of a ship and is crucial to a vessel's operation. Any issues with shaft line equipment can result in damage and render a vessel off-hire during a voyage. Therefore, the preservation of an ideal shaft line with all shaft line requipment in the best possible working order is vital throughout a vessel's entire lifespan.

Ship design and operation technologies have evolved over the years, creating greater efficiencies and extended lifespans for shaft line equipment. Wärtsilä Shaft Line Solutions have significantly advanced innovation in this technology field, fuelled by insight on market needs collected from end users in a systematic way. The latest innovation from Wärtsilä Shaft Line Solutions is a modular shaft line equipment package, FuTube, which was launched in March 2024 and developed based on extensive end user feedback and an approach by Wärtsilä to re-route traditional approaches to the procurement of shaft line equipment so that end users can specify individual SLS makers.

.jpg)

FuTube: a story of listening and learning

The development of the FuTube SLS package started in 2017 when Wärtsilä Shaft Line Solutions embarked on a project to listen to and learn from the industry. The aim was to develop a new offering that comprises Wärtsilä's entire portfolio of shaft line equipment in one complete package.

End user feedback gathered across 3,800 responses moulded the SLS package development. Through end users grading SLS aspects on positive business impact versus negative business impact, Wärtsilä could pinpoint end user pain points. These pain points were identified by layering aspects where the negative impact of a damaging scenario is high and the need for a solution is high. Pain points were taken into R&D activities to develop the new package solution in cross-collaboration between Wärtsilä's International teams.

Based on the feedback collected, the resounding and encouraging consensus is that, although the current state suffices for our operations, embracing these improvements would undoubtedly elevate our performance and effectiveness. the overarching three principal needs from end users were lowering operational costs, making the life of the crew easier and avoiding damages that stop vessels from operating.

Addressing end user pain points

For ship operators and managers, a vessel becoming offhire during a voyage is a nightmare scenario that creates unplanned OPEX costs associated with fixing the problem and getting a vessel back in operation as soon as possible. The prevention of oil leaks or spills with 100% failsafe stern tubes and seals is a high need from end users alongside bearing damage. For example, a shaft's whirling effects damaging bearings. Another example of a high need for end users is not having to stop a voyage because of damage taking place because the crew are unaware of any existing dangerous shaft line effects.

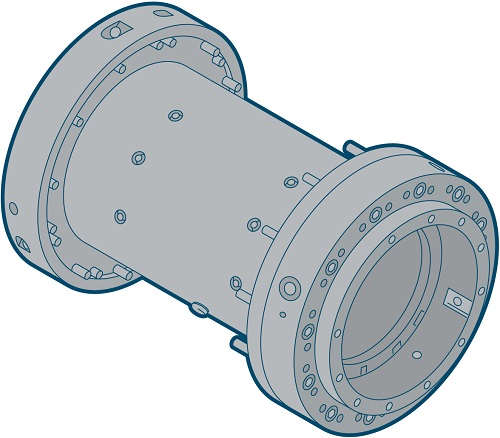

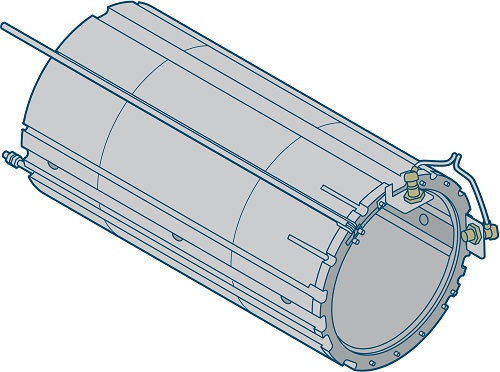

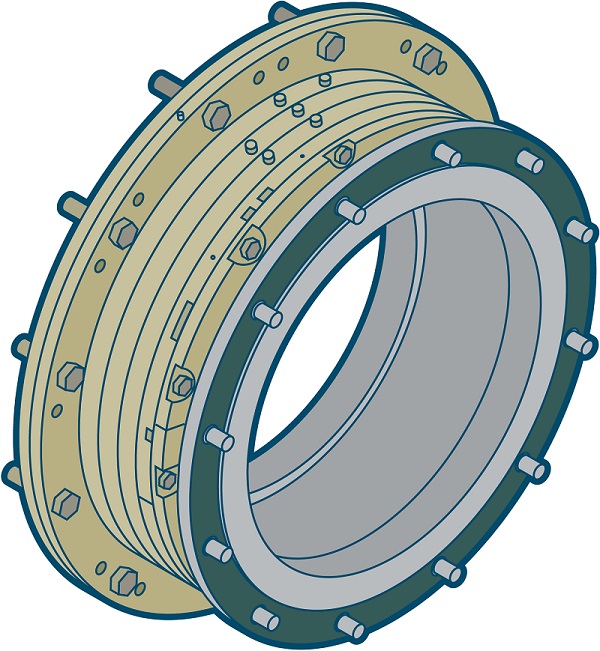

The resulting modular SLS package, FuTube, incorporates all Wärtsilä shaft line technologies,

The Evotube System, a robust, eco-friendly system with a compact design that maximizes cargo space. It supports both oil and water lubrication systems and enables easy transitions between them, ensuring future-proofing for vessels.

The Intellisafe Bearing, a revolutionary smart bearing with advanced sensors and real-time analytics. It proactively responds to adverse conditions, preventing failures, and reducing downtime and costs for clients.

10 year AirGuard Seal, an evolution with extended maintenance intervals, cutting costs and promoting sustainability in maritime operations.

Shaft Line Monitoring Equipment a system offering real-time insights into the shaft line's operational health. By monitoring key parameters like shaft movements and vibrations, it enables proactive maintenance and early issue detection. This prevents breakdowns, optimizing shaft line performance.

Offering a comprehensive package that can be acquired in its entirety or as individual products, providing flexibility to tailor solutions to each customer's specific needs. During the development phase, all the individual shaft line technologies were assembled on a test rig at the Wärtsilä Shaft Line Solutions factory site in Spain. This test rig was meticulously designed to replicate real-world scenarios and rigorously validate performance and reliability.

| Read More: Wärtsilä again chosen to supply cargo handling systems for newbuild Solvang vessels |

Driving innovation in the SLS market

It is not just end user feedback that this modular SLS package is satisfying. In creating an SLS package, Wärtsilä is positively disrupting traditional approaches to shaft line equipment procurement in the industry. It is standard practice for shipowners to write the ship specifications but not to specify the shaft line make. Then, the shipyard chooses the shaft line equipment maker based on price, considering all makers and shaft lines as standard. Finally, the ship manager is the stakeholder in the chain, who buys the shaft line equipment, spares, and services during aftersales.

To support this, Wärtsilä is making the procurement of complete shaft line solutions as simple as possible by ensuring that an entire shaft line solutions package can be procured from them, as a SLS maker, by the shipyard following a request from the ship owner.

Simplifying shaft line equipment use

In supporting end users to simplify shaft line equipment operation and maintenance, Wärtsilä is supporting the industry to minimise disruptions caused by shaft line damages, offhire costs, and negative environmental impacts.

Operating 75 countries and supplying products for the whole shaft line, from seals and bearings to couplings, stern tubes and condition monitoring systems, makes it possible for an entire propulsion system to be fully serviced by Wärtsilä. With the introduction of the FuTube SLS package, end users can simplify shaft lines even further by selecting a complete package of solutions from one provider only that can access Wärtsilä's global servicing and support network.

Source:Wärtsilä

| Read Here | |

|

|